BUILDING BASICS

CONCRETE

Concrete is among the most durable building materials available. However, concrete can deteriorate if it is not used and maintained properly. The following is a description of the typical conditions that may cause concrete deterioration and recommended solutions to these problems:

CONTACT US

ABOUT CONCRETE

Inadequate Materials

Poor quality concrete can cause building deterioration. This condition may manifest itself when the ingredients of the mix are improperly calculated.

To determine concrete quality, core samples are taken from various locations for evaluation. It is a good idea to take core samples from both deteriorated areas and those that appear to be undamaged. Differences in the concrete may provide clues to the reason for the deterioration.

Construction & Design Errors

Construction errors occur when what is actually built deviates from the original specifications or prevailing standards. Design errors occur when mistakes are made in the original specification. Design errors may also include then absence of drip edges at underside of a slab, or expansion and control joints that are spaced too far apart.

Although construction defects usually cannot be completely corrected, efforts must be made to alleviate their detrimental effects.

Insufficient Concrete Cover Over Reinforcing Bars

A typical construction error is insufficient concrete cover over reinforcing bars. Rust stains on spandrels or columns may indicate inadequate concrete cover.

The thickness of the repair concrete should be increased to provide proper coverage.

MISALIGNED COLUMNS FROM ONE LEVEL TO ANOTHER

Misaligned columns from one level to another are usually a clue that the reinforcing cage was improperly positioned.

Electrical Conduit Placed Too Close To The Surface

Electrical conduit placed too close to the surface can promote spalling.

Excessive Deflection In Beams Caused By Premature Removal Of Shoring

Premature removal of shoring can cause excessive deflection in beams. Deflection can cause distorted window frames, problems with window seals, and cracked masonry.

Honeycombing

Honeycombing or segregation of the aggregate results from concrete placement problems in small or substantially reinforced columns.

Spalling & Delamination

Spalling and delamination are usually the result of internal pressure caused by corroding reinforcing steel. Spalls are areas where concrete has broken away from the wall. Small spalls, or pop outs, can occur at edges where bar ends terminate near the concrete surface or at other localized areas of shallow concrete cover. Larger spalls occur near embedments and where long sections of reinforcing steel, with insufficient cover, run parallel to the concrete’s surface.

Delaminations are areas where the concrete has lost its bond with the reinforcing steel. The resulting planar cracks, that run parallel to the surface, are due to corrosion of rebar near the top surface or below embedments. Delaminations can be detected by tapping the concrete with a hammer. A hollow sound indicates a delaminated area.

Spalls and delaminations on the building façade may be only warnings of more extensive structural damage extending into the building.

Repairs inside the building are more expensive, often requiring shoring and bracing of windows or walls and protection of interior spaces from dust and weather.

RECENT BLOG POSTS

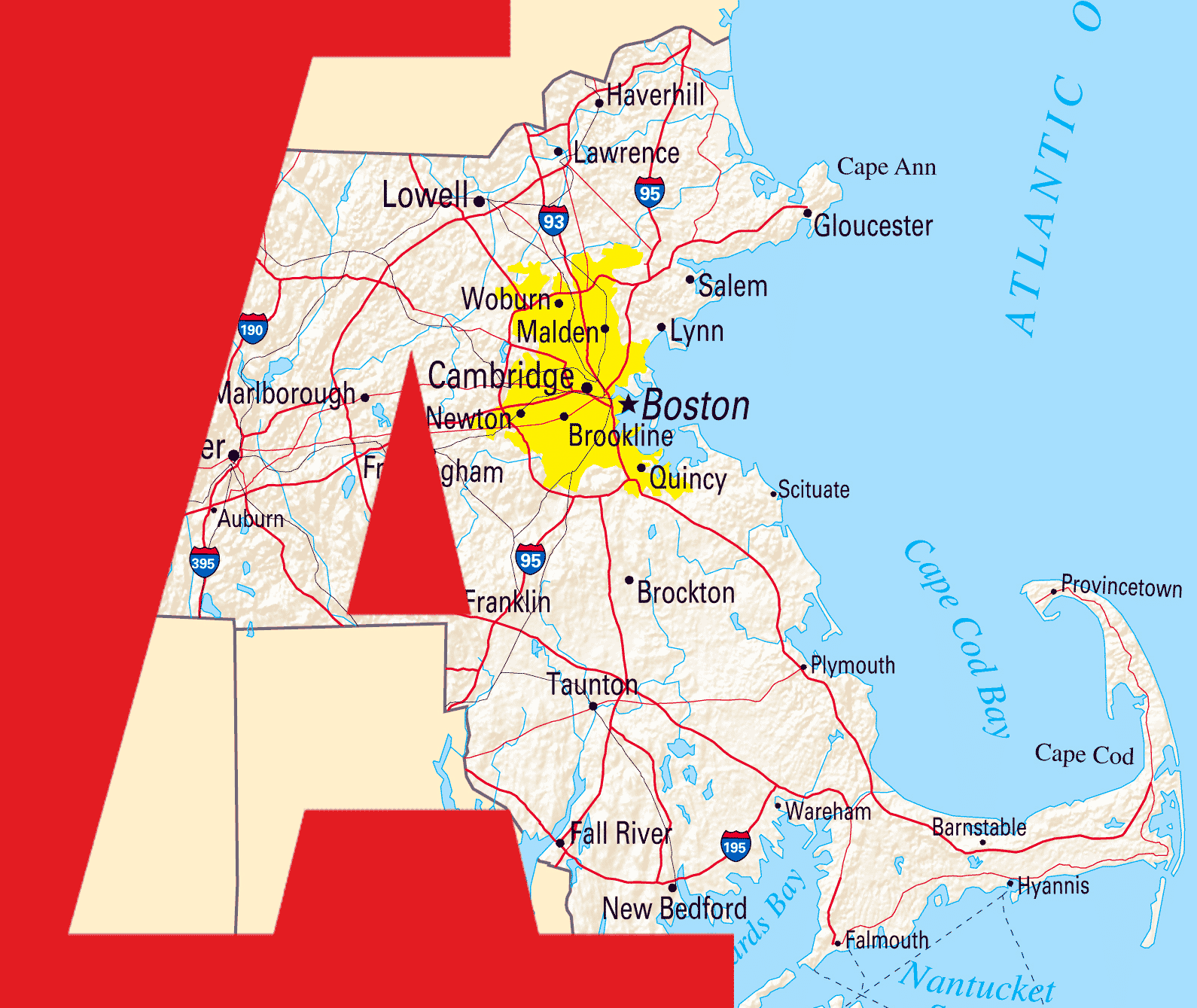

Proudly Serving Greater Boston

& Eastern Massachusetts

Wet Weather and Commercial Masonry Restoration in MA

Here’s a closer look at how wet weather and prolonged moisture affect commercial masonry restoration in MA.

Read More

Concrete vs. Brick Restoration Part 2: Differences

To better understand the process and importance of concrete restoration in Massachusetts, let’s take a look at how it differs from brick restoration.

Read More