Structural masonry repairs require precise methods to ensure the building remains safe, functional, and built to last. A key element in these repairs is the lintel, a structural component placed above windows and doors to support the weight of the masonry wall above the opening. As experts in masonry repair in Massachusetts, our team at Abbot Building Restoration is uniquely equipped to explain this crucial component.

What Is a Lintel?

In brick masonry walls, lintels can be made from various materials, including:

- Reinforced brick masonry

- Brick masonry arches

- Precast concrete

- Structural steel shapes

Lintels typically rest on the topmost course of bricks that aligns with the top of the window or door frame. To further reinforce the wall above the opening, steel reinforcing bars may be installed within the masonry above the lintel.

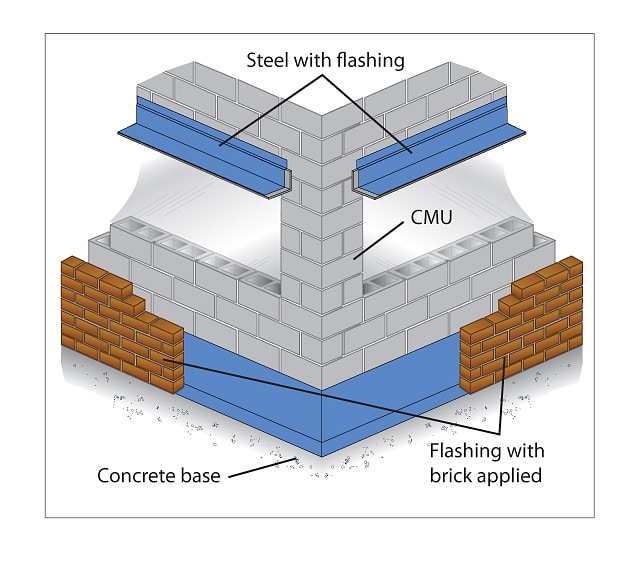

An example of this process is the installation of structural steel lintels, where the initial steel placement is followed by completing the brick veneer across the face of the CMU (concrete masonry unit) wall. The masonry continues upward along both sides of the lintel to establish proper bearing points.

Importance of Proper Lintel Design

When it comes to masonry repair in Massachusetts, lintels must be properly designed, not selected based on outdated “rule-of-thumb” methods or arbitrary structural sections. Accurate load analysis and stress calculations must be performed to prevent issues like:

- Structural cracks above window and door openings

- Spalling (surface flaking or breaking of masonry)

- Excessive deflection due to under-designed lintels

Many masonry wall failures stem from poorly designed or installed lintels and incorrect flashing details.

Moisture Control Around Openings

Effective moisture control is also essential in masonry repairs. All wall openings must include proper flashing systems to direct water to the outside. Flashing should be installed over the lintel to ensure that any water penetrating the masonry is redirected safely. Improper flashing is one of the most common causes of water leaks around windows and doors.

Common Types of Structural Steel Lintels

Several types of steel lintels are used in masonry construction, including:

- Single-angle lintels (standard in cavity or veneer walls)

- Steel beams with plates (for solid walls)

- Shelf angles (in brick veneer panel walls)

Lintel Installation Process

Installing steel lintels in masonry walls follows a conventional process:

- Masonry is built to the height of the opening

- The lintel is placed over the opening

- Masonry work continues above the lintel to complete the wall

Proper installation is crucial for maintaining long-term performance and ensuring structural stability.

Abbot Building Restoration | Professional Masonry Repair in Massachusetts

If you need expert masonry repair in Massachusetts, contact Abbot Building Restoration today at 617-445-0274. Our team specializes in structural repair and historic restorations to preserve and protect masonry structures.